-

HOME

- Hakkımızda

- CNR 125

- Yarı Römork

- Terminal Semi-Trailer

- Defense industry

- Full-Trailer

- Central Axle Full Trailer

- Turntable Full Trailer

- Truck Body

- Tipper Truck Body

- Silo Truck Body

- Truck Box Body

- Tanker Truck Body

- Semi-Trailer

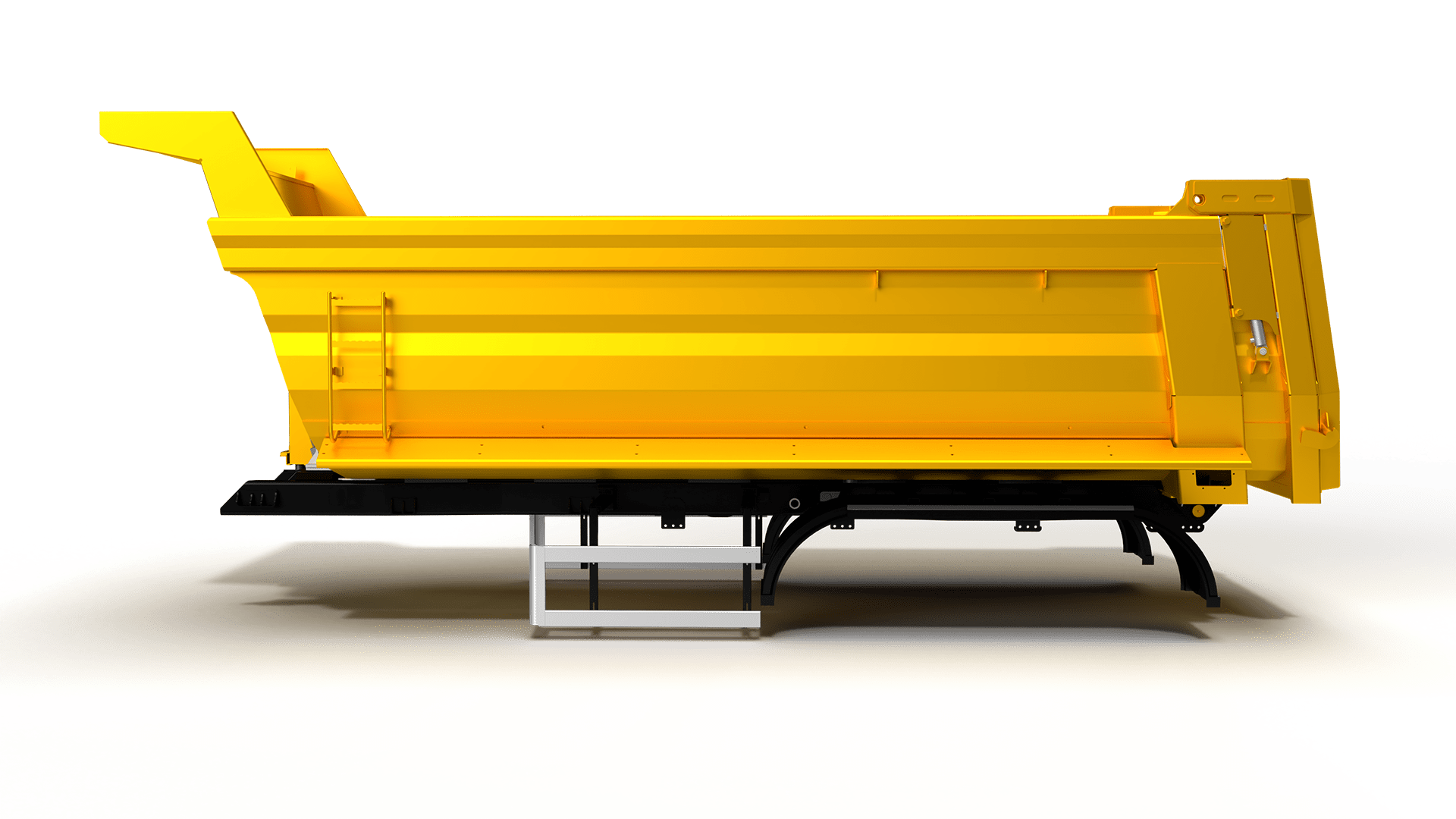

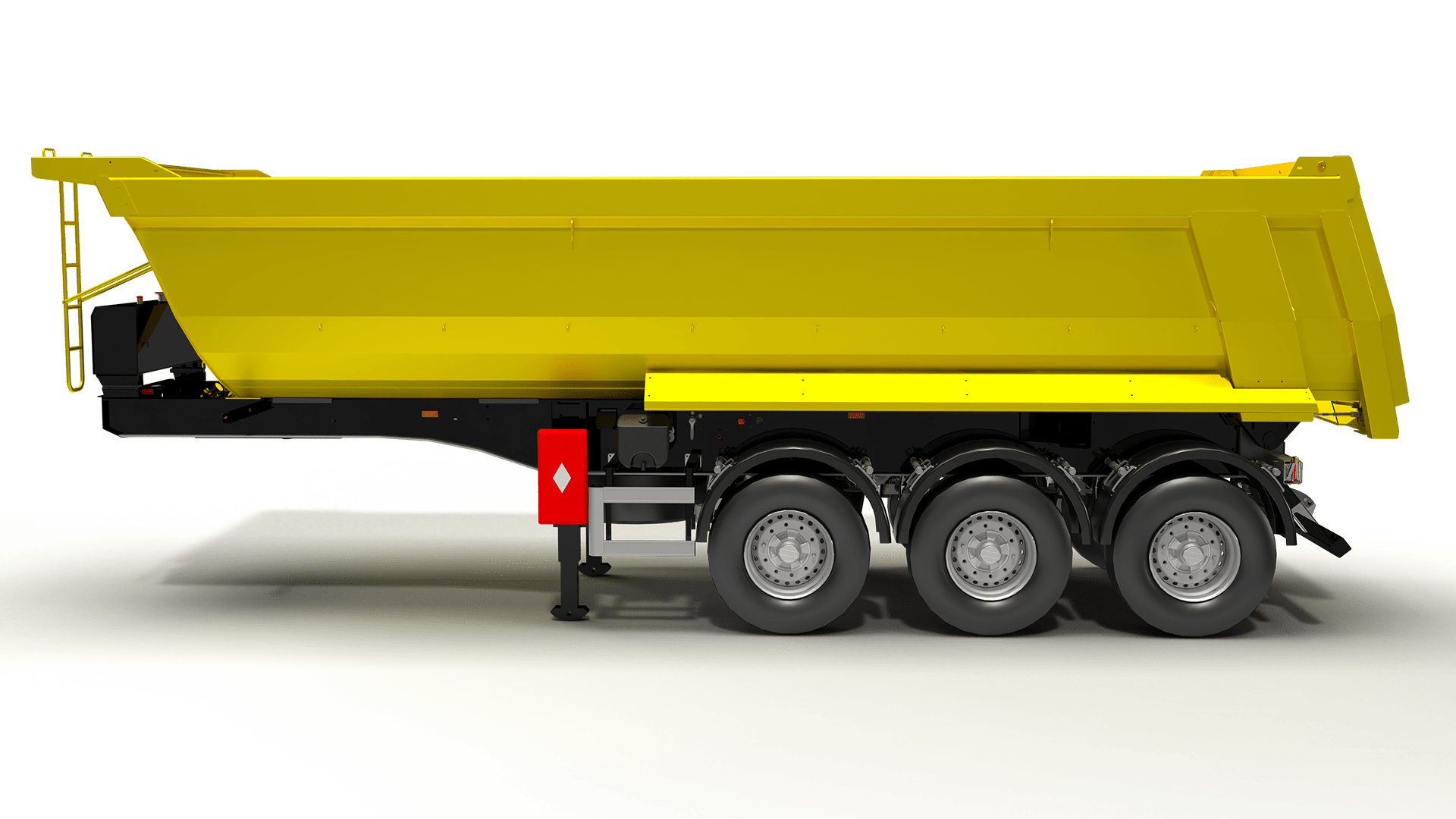

- Half-Pipe Tipping Semi-Trailer

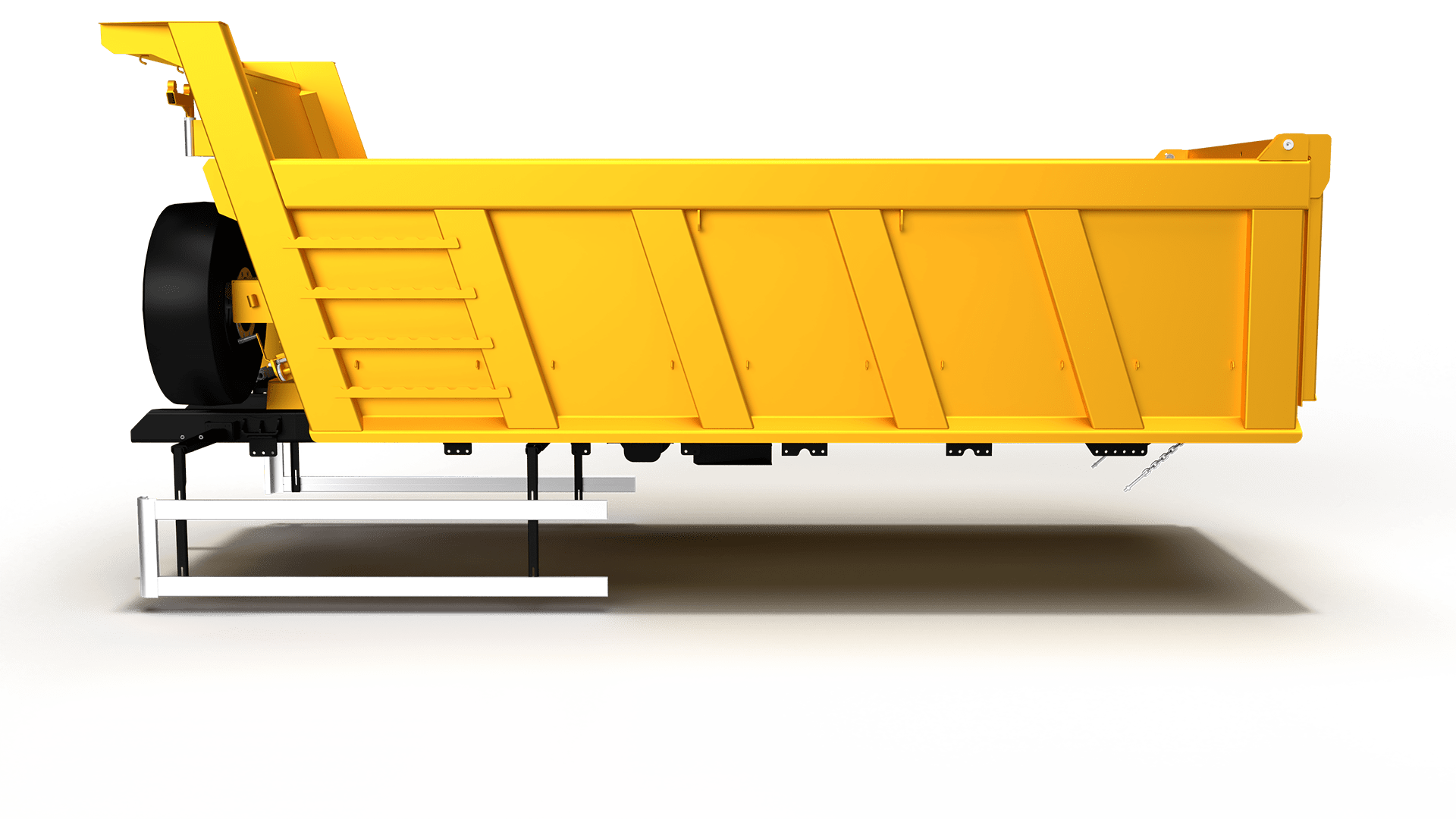

- Scrap Carrier Tipping Semi-Trailer

- Platform Semi-Trailer with Side-Drops

- Platform Semi-Trailer

- Container Carrier Semi-Trailer

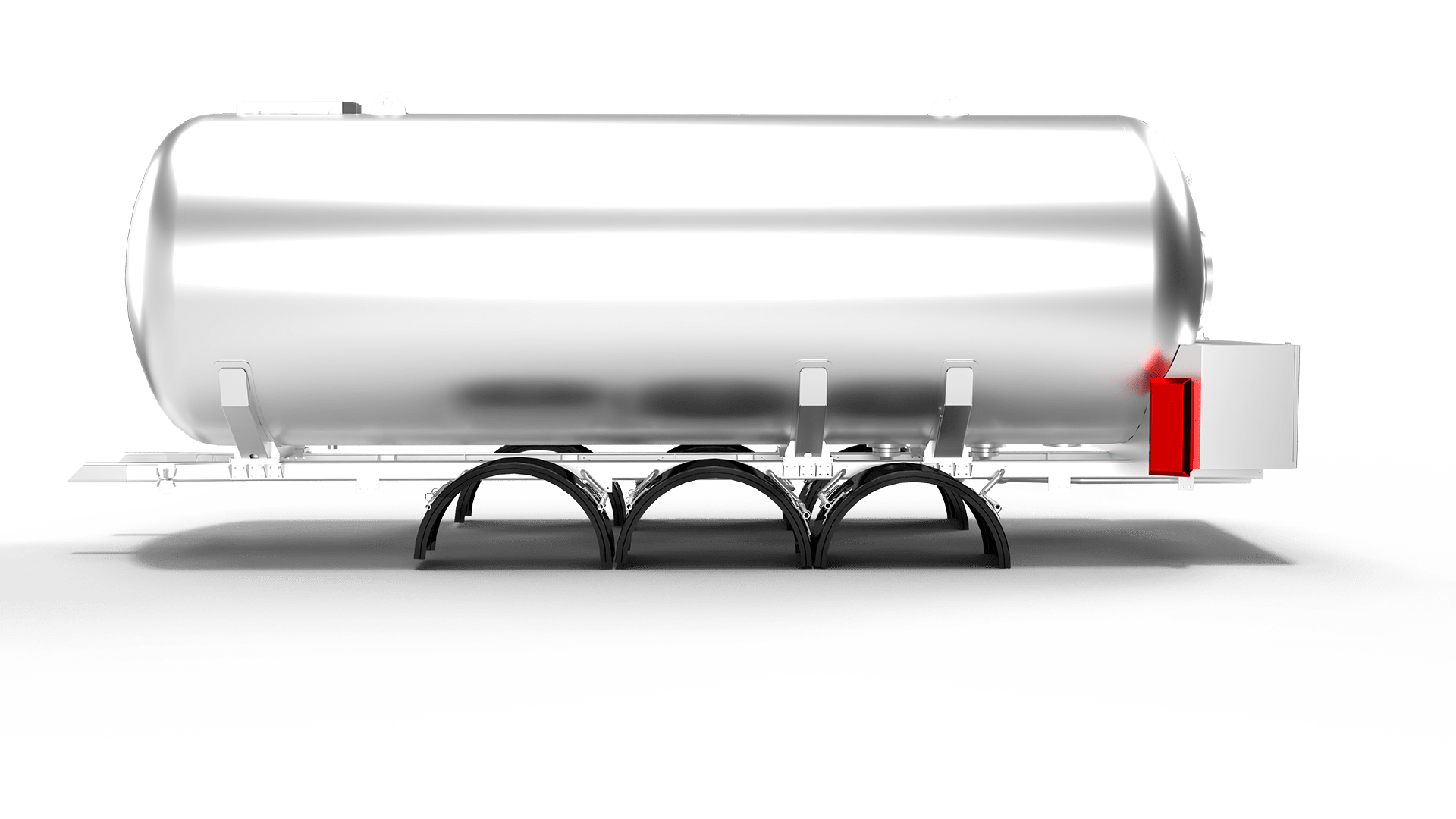

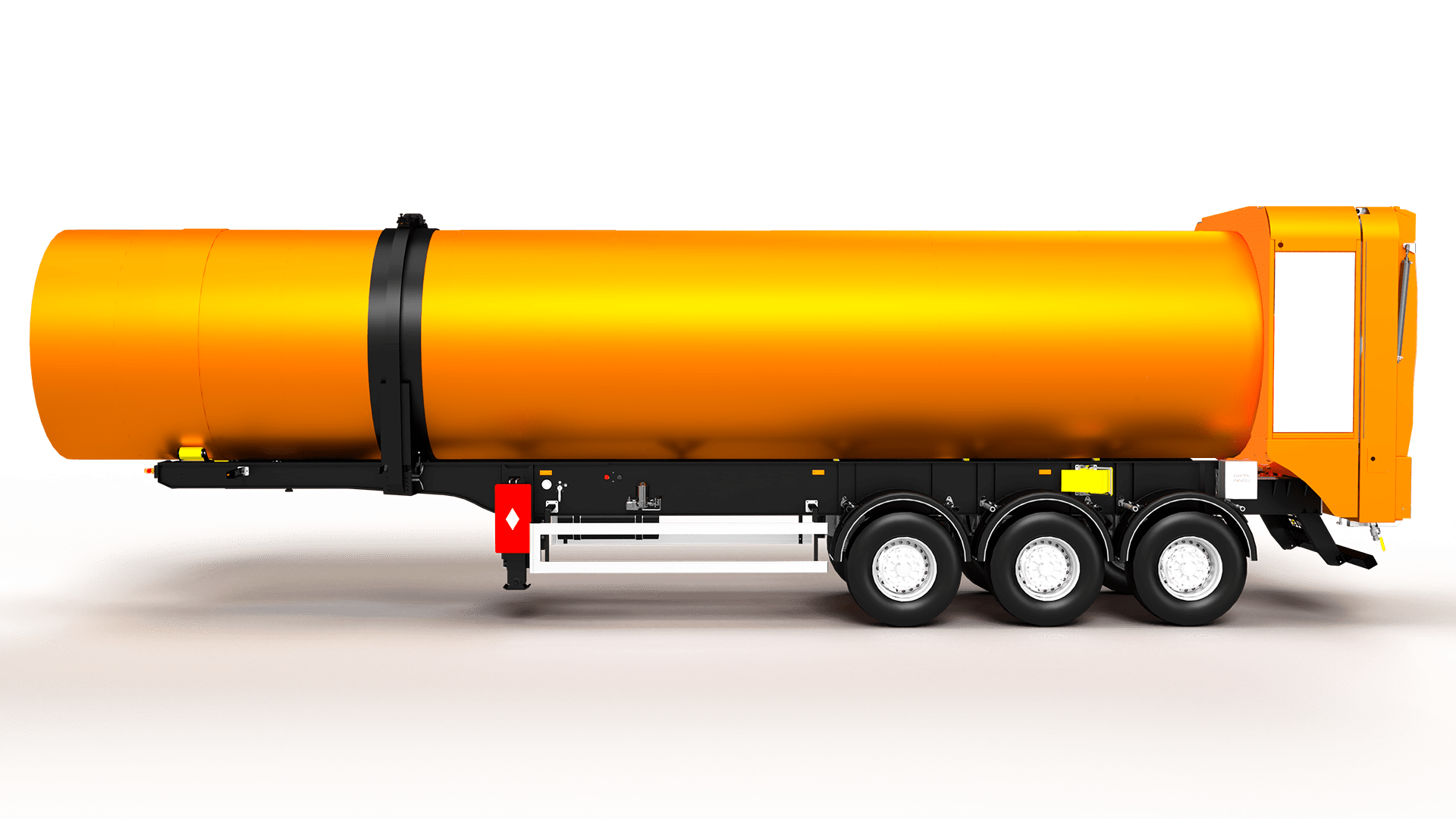

- Tanker Semi-Trailer

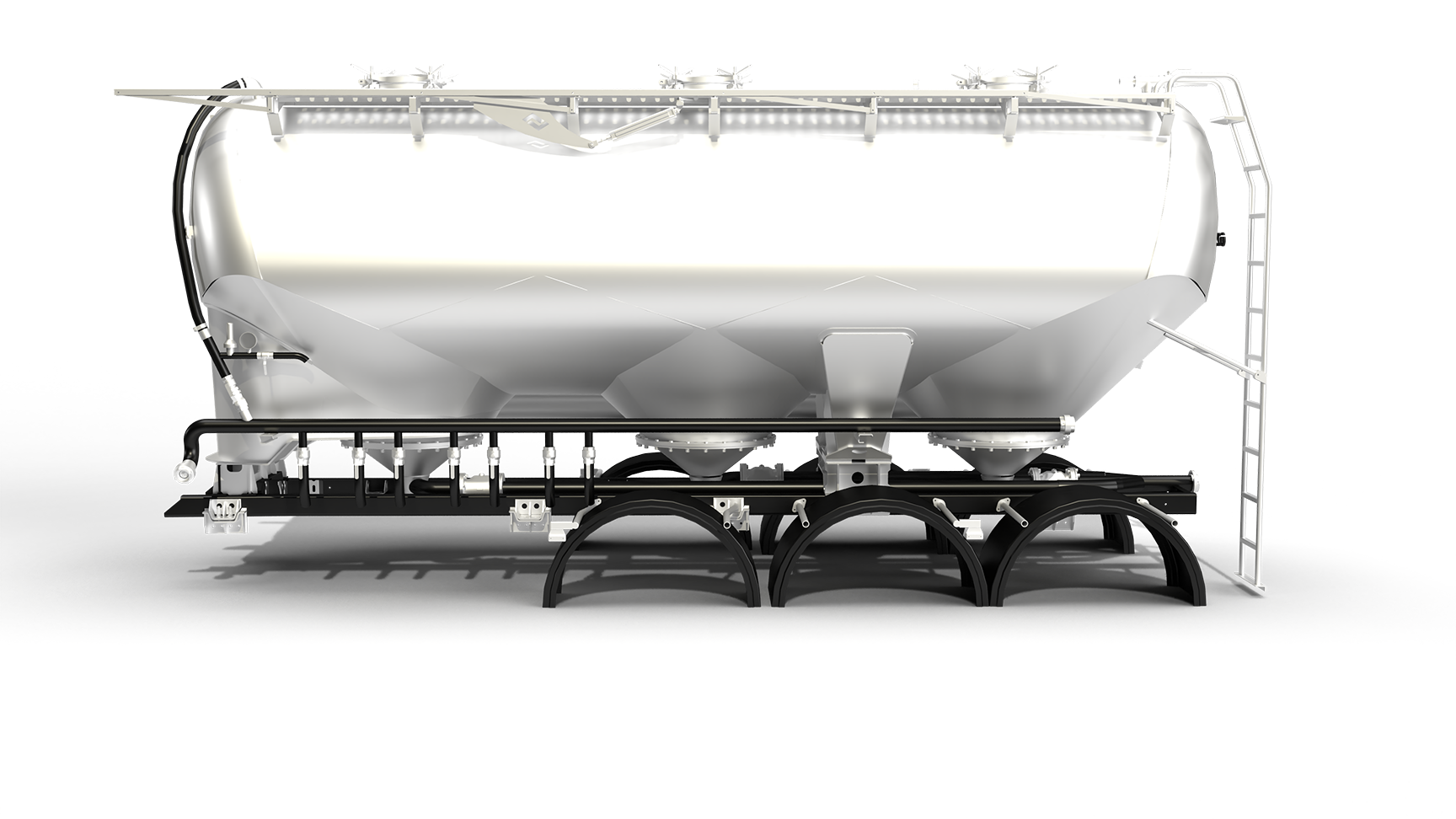

- Silo Semi-Trailer

- Garbage Transfer Semi-Trailer

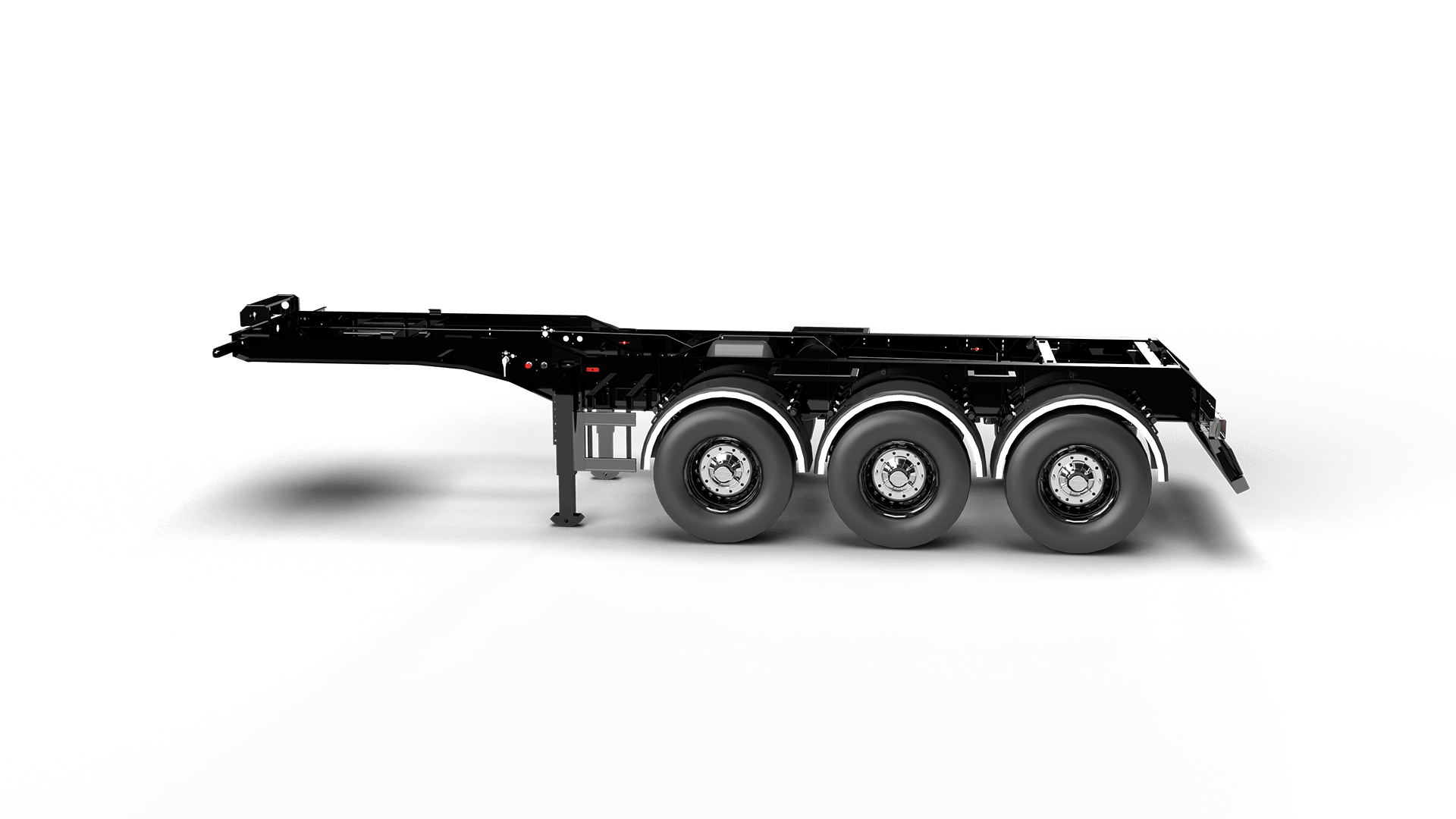

- Chassis

- Politikamız

- CNR 125

- Yarı Römork

- Terminal Semi-Trailer

- Defense industry

- Full-Trailer

- Central Axle Full Trailer

- Turntable Full Trailer

- Truck Body

- Tipper Truck Body

- Silo Truck Body

- Truck Box Body

- Tanker Truck Body

- Semi-Trailer

- Half-Pipe Tipping Semi-Trailer

- Scrap Carrier Tipping Semi-Trailer

- Platform Semi-Trailer with Side-Drops

- Platform Semi-Trailer

- Container Carrier Semi-Trailer

- Tanker Semi-Trailer

- Silo Semi-Trailer

- Garbage Transfer Semi-Trailer

- Chassis

- Değerlerimiz

- CNR 125

- Yarı Römork

- Terminal Semi-Trailer

- Defense industry

- Full-Trailer

- Central Axle Full Trailer

- Turntable Full Trailer

- Truck Body

- Tipper Truck Body

- Silo Truck Body

- Truck Box Body

- Tanker Truck Body

- Semi-Trailer

- Half-Pipe Tipping Semi-Trailer

- Scrap Carrier Tipping Semi-Trailer

- Platform Semi-Trailer with Side-Drops

- Platform Semi-Trailer

- Container Carrier Semi-Trailer

- Tanker Semi-Trailer

- Silo Semi-Trailer

- Garbage Transfer Semi-Trailer

- Chassis

- Tanıtım Filmlerimiz

- CNR 125

- Yarı Römork

- Terminal Semi-Trailer

- Defense industry

- Full-Trailer

- Central Axle Full Trailer

- Turntable Full Trailer

- Truck Body

- Tipper Truck Body

- Silo Truck Body

- Truck Box Body

- Tanker Truck Body

- Semi-Trailer

- Half-Pipe Tipping Semi-Trailer

- Scrap Carrier Tipping Semi-Trailer

- Platform Semi-Trailer with Side-Drops

- Platform Semi-Trailer

- Container Carrier Semi-Trailer

- Tanker Semi-Trailer

- Silo Semi-Trailer

- Garbage Transfer Semi-Trailer

- Chassis

- İnsan Kaynakları

- CNR 125

- Yarı Römork

- Terminal Semi-Trailer

- Defense industry

- Full-Trailer

- Central Axle Full Trailer

- Turntable Full Trailer

- Truck Body

- Tipper Truck Body

- Silo Truck Body

- Truck Box Body

- Tanker Truck Body

- Semi-Trailer

- Half-Pipe Tipping Semi-Trailer

- Scrap Carrier Tipping Semi-Trailer

- Platform Semi-Trailer with Side-Drops

- Platform Semi-Trailer

- Container Carrier Semi-Trailer

- Tanker Semi-Trailer

- Silo Semi-Trailer

- Garbage Transfer Semi-Trailer

- Chassis

- Basın Merkezi

- CNR 125

- Yarı Römork

- Terminal Semi-Trailer

- Defense industry

- Full-Trailer

- Central Axle Full Trailer

- Turntable Full Trailer

- Truck Body

- Tipper Truck Body

- Silo Truck Body

- Truck Box Body

- Tanker Truck Body

- Semi-Trailer

- Half-Pipe Tipping Semi-Trailer

- Scrap Carrier Tipping Semi-Trailer

- Platform Semi-Trailer with Side-Drops

- Platform Semi-Trailer

- Container Carrier Semi-Trailer

- Tanker Semi-Trailer

- Silo Semi-Trailer

- Garbage Transfer Semi-Trailer

- Chassis

- Hakkımızda

-

CORPORATE▼

- About Us

- CNR 125

- Yarı Römork

- Terminal Semi-Trailer

- Defense industry

- Full-Trailer

- Central Axle Full Trailer

- Turntable Full Trailer

- Truck Body

- Tipper Truck Body

- Silo Truck Body

- Truck Box Body

- Tanker Truck Body

- Semi-Trailer

- Half-Pipe Tipping Semi-Trailer

- Scrap Carrier Tipping Semi-Trailer

- Platform Semi-Trailer with Side-Drops

- Platform Semi-Trailer

- Container Carrier Semi-Trailer

- Tanker Semi-Trailer

- Silo Semi-Trailer

- Garbage Transfer Semi-Trailer

- Chassis

- Our Policy

- CNR 125

- Yarı Römork

- Terminal Semi-Trailer

- Defense industry

- Full-Trailer

- Central Axle Full Trailer

- Turntable Full Trailer

- Truck Body

- Tipper Truck Body

- Silo Truck Body

- Truck Box Body

- Tanker Truck Body

- Semi-Trailer

- Half-Pipe Tipping Semi-Trailer

- Scrap Carrier Tipping Semi-Trailer

- Platform Semi-Trailer with Side-Drops

- Platform Semi-Trailer

- Container Carrier Semi-Trailer

- Tanker Semi-Trailer

- Silo Semi-Trailer

- Garbage Transfer Semi-Trailer

- Chassis

- Our Values

- CNR 125

- Yarı Römork

- Terminal Semi-Trailer

- Defense industry

- Full-Trailer

- Central Axle Full Trailer

- Turntable Full Trailer

- Truck Body

- Tipper Truck Body

- Silo Truck Body

- Truck Box Body

- Tanker Truck Body

- Semi-Trailer

- Half-Pipe Tipping Semi-Trailer

- Scrap Carrier Tipping Semi-Trailer

- Platform Semi-Trailer with Side-Drops

- Platform Semi-Trailer

- Container Carrier Semi-Trailer

- Tanker Semi-Trailer

- Silo Semi-Trailer

- Garbage Transfer Semi-Trailer

- Chassis

- Our Promotional Films

- CNR 125

- Yarı Römork

- Terminal Semi-Trailer

- Defense industry

- Full-Trailer

- Central Axle Full Trailer

- Turntable Full Trailer

- Truck Body

- Tipper Truck Body

- Silo Truck Body

- Truck Box Body

- Tanker Truck Body

- Semi-Trailer

- Half-Pipe Tipping Semi-Trailer

- Scrap Carrier Tipping Semi-Trailer

- Platform Semi-Trailer with Side-Drops

- Platform Semi-Trailer

- Container Carrier Semi-Trailer

- Tanker Semi-Trailer

- Silo Semi-Trailer

- Garbage Transfer Semi-Trailer

- Chassis

- Human Resources

- CNR 125

- Yarı Römork

- Terminal Semi-Trailer

- Defense industry

- Full-Trailer

- Central Axle Full Trailer

- Turntable Full Trailer

- Truck Body

- Tipper Truck Body

- Silo Truck Body

- Truck Box Body

- Tanker Truck Body

- Semi-Trailer

- Half-Pipe Tipping Semi-Trailer

- Scrap Carrier Tipping Semi-Trailer

- Platform Semi-Trailer with Side-Drops

- Platform Semi-Trailer

- Container Carrier Semi-Trailer

- Tanker Semi-Trailer

- Silo Semi-Trailer

- Garbage Transfer Semi-Trailer

- Chassis

- Press Center

- CNR 125

- Yarı Römork

- Terminal Semi-Trailer

- Defense industry

- Full-Trailer

- Central Axle Full Trailer

- Turntable Full Trailer

- Truck Body

- Tipper Truck Body

- Silo Truck Body

- Truck Box Body

- Tanker Truck Body

- Semi-Trailer

- Half-Pipe Tipping Semi-Trailer

- Scrap Carrier Tipping Semi-Trailer

- Platform Semi-Trailer with Side-Drops

- Platform Semi-Trailer

- Container Carrier Semi-Trailer

- Tanker Semi-Trailer

- Silo Semi-Trailer

- Garbage Transfer Semi-Trailer

- Chassis

- About Us

- PRODUCTS▼

-

Defense industry▼

- Tank Carrier Low-Bed

- CNR 125

- Yarı Römork

- Terminal Semi-Trailer

- Defense industry

- Full-Trailer

- Central Axle Full Trailer

- Turntable Full Trailer

- Truck Body

- Tipper Truck Body

- Silo Truck Body

- Truck Box Body

- Tanker Truck Body

- Semi-Trailer

- Half-Pipe Tipping Semi-Trailer

- Scrap Carrier Tipping Semi-Trailer

- Platform Semi-Trailer with Side-Drops

- Platform Semi-Trailer

- Container Carrier Semi-Trailer

- Tanker Semi-Trailer

- Silo Semi-Trailer

- Garbage Transfer Semi-Trailer

- Chassis

- Mobile Field Containers

- CNR 125

- Yarı Römork

- Terminal Semi-Trailer

- Defense industry

- Full-Trailer

- Central Axle Full Trailer

- Turntable Full Trailer

- Truck Body

- Tipper Truck Body

- Silo Truck Body

- Truck Box Body

- Tanker Truck Body

- Semi-Trailer

- Half-Pipe Tipping Semi-Trailer

- Scrap Carrier Tipping Semi-Trailer

- Platform Semi-Trailer with Side-Drops

- Platform Semi-Trailer

- Container Carrier Semi-Trailer

- Tanker Semi-Trailer

- Silo Semi-Trailer

- Garbage Transfer Semi-Trailer

- Chassis

- Land Vehicles Refueling Vehicle-Aktan

- CNR 125

- Yarı Römork

- Terminal Semi-Trailer

- Defense industry

- Full-Trailer

- Central Axle Full Trailer

- Turntable Full Trailer

- Truck Body

- Tipper Truck Body

- Silo Truck Body

- Truck Box Body

- Tanker Truck Body

- Semi-Trailer

- Half-Pipe Tipping Semi-Trailer

- Scrap Carrier Tipping Semi-Trailer

- Platform Semi-Trailer with Side-Drops

- Platform Semi-Trailer

- Container Carrier Semi-Trailer

- Tanker Semi-Trailer

- Silo Semi-Trailer

- Garbage Transfer Semi-Trailer

- Chassis

- Aircraft Refueling Vehicle-Aktan

- CNR 125

- Yarı Römork

- Terminal Semi-Trailer

- Defense industry

- Full-Trailer

- Central Axle Full Trailer

- Turntable Full Trailer

- Truck Body

- Tipper Truck Body

- Silo Truck Body

- Truck Box Body

- Tanker Truck Body

- Semi-Trailer

- Half-Pipe Tipping Semi-Trailer

- Scrap Carrier Tipping Semi-Trailer

- Platform Semi-Trailer with Side-Drops

- Platform Semi-Trailer

- Container Carrier Semi-Trailer

- Tanker Semi-Trailer

- Silo Semi-Trailer

- Garbage Transfer Semi-Trailer

- Chassis

- PMKI-METI Trailers

- CNR 125

- Yarı Römork

- Terminal Semi-Trailer

- Defense industry

- Full-Trailer

- Central Axle Full Trailer

- Turntable Full Trailer

- Truck Body

- Tipper Truck Body

- Silo Truck Body

- Truck Box Body

- Tanker Truck Body

- Semi-Trailer

- Half-Pipe Tipping Semi-Trailer

- Scrap Carrier Tipping Semi-Trailer

- Platform Semi-Trailer with Side-Drops

- Platform Semi-Trailer

- Container Carrier Semi-Trailer

- Tanker Semi-Trailer

- Silo Semi-Trailer

- Garbage Transfer Semi-Trailer

- Chassis

- Tank Carrier Low-Bed

- Service Network

- Contact